SERVICES

Mechanical Engineering

At Byte Lab, we design the mechanical core of your product — transforming electronics into complete, market-ready devices. Our focus goes beyond looks; we engineer with purpose, precision, and production in mind.

EXPERTISE IN ACTION

Services We Offer

Each of these services is delivered through a structured and well-defined project execution framework. From initial planning to final delivery, we follow clear procedures and assign dedicated roles to manage every stage of development effectively.

ENCLOSURE DESIGN

We create custom enclosures that not only protect your electronics but also enhance usability and visual appeal. Every housing is tailored to your product’s requirements – from ergonomic handheld gadgets to ruggedized industrial units – ensuring your technology is safe, accessible, and looks great doing its job. A well-designed enclosure also drives down lifecycle costs by preventing damage and downtime, so your product makes a strong first impression and stands the test of time.

INDUSTRIAL & MECHANICAL DESIGN

From concept sketches to detailed 3D CAD models, our team blends form and function into one seamless process. We work iteratively to refine the product’s look and feel alongside its internal mechanics, aligning aesthetic design, user experience, and engineering practicality. The result is a device that is sleek and user-friendly without compromising on performance or manufacturability.

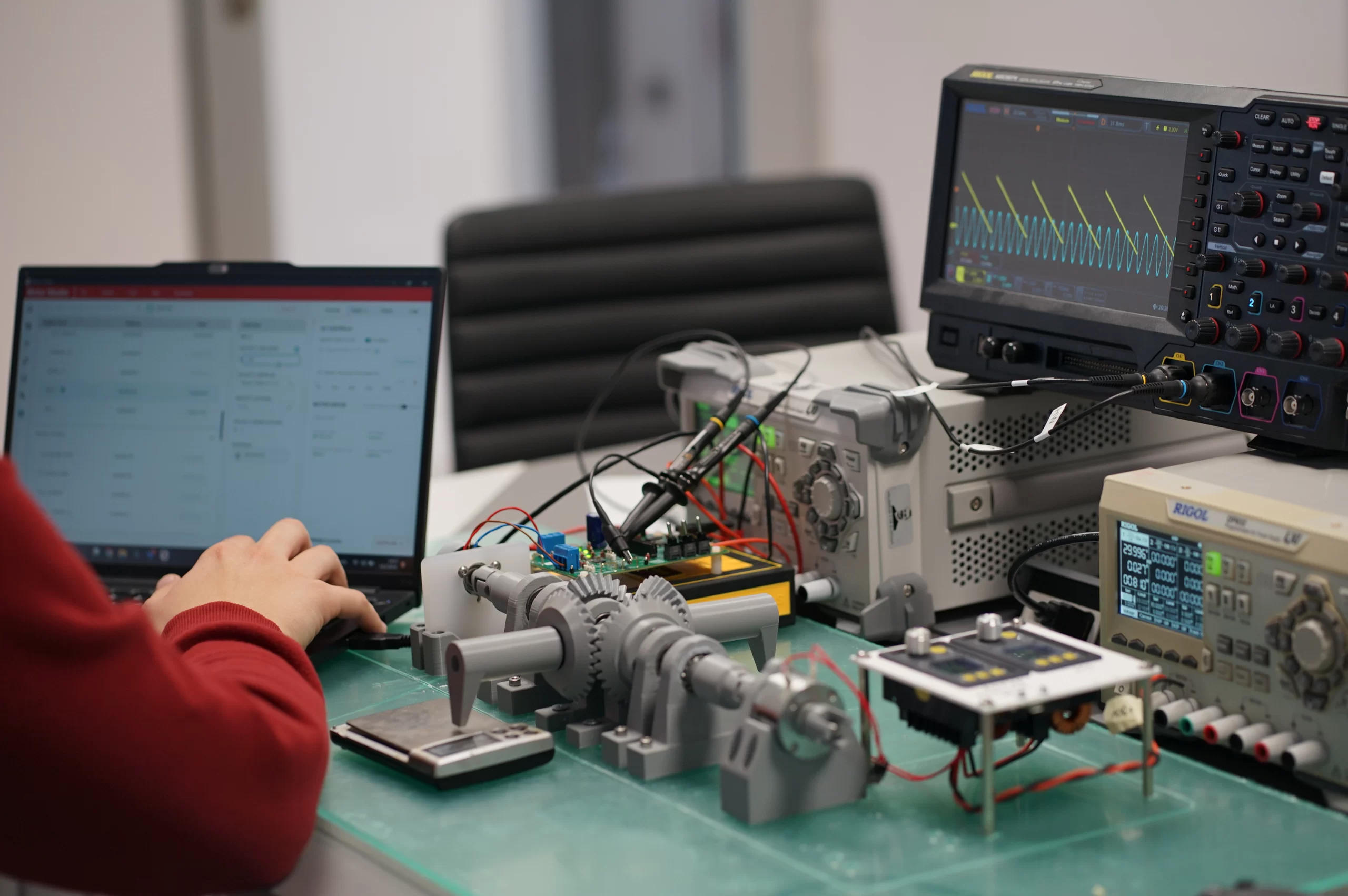

RAPID PROTOTYPING

Byte Lab’s in-house prototyping capabilities allow us to turn ideas into physical prototypes in a flash. We treat enclosure prototyping as just as critical as electronics prototyping, using 3D printing, CNC machining, and other rapid fabrication tools to test and validate designs early. This fail-fast, iterate-fast approach means we can quickly evaluate ergonomics, assembly, and durability, then refine the design long before expensive production tooling. The benefit to you is a shorter development cycle and a proof-of-concept you can touch and feel, giving confidence to stakeholders and investors.

DESIGN FOR MANUFACTURING (DFM)

We engineer every detail with manufacturing in mind. Our mechanical designs emphasize ease of production, cost-effectiveness, and quality control from the outset. We carefully select materials and define part geometries to reduce the need for manual assembly and to ensure consistency at scale. By involving DFM at each step, we help you avoid budget overruns caused by complex or impractical designs. The payoff is a design that moves into production smoothly – minimizing rework, lowering unit costs, and accelerating time-to-market.

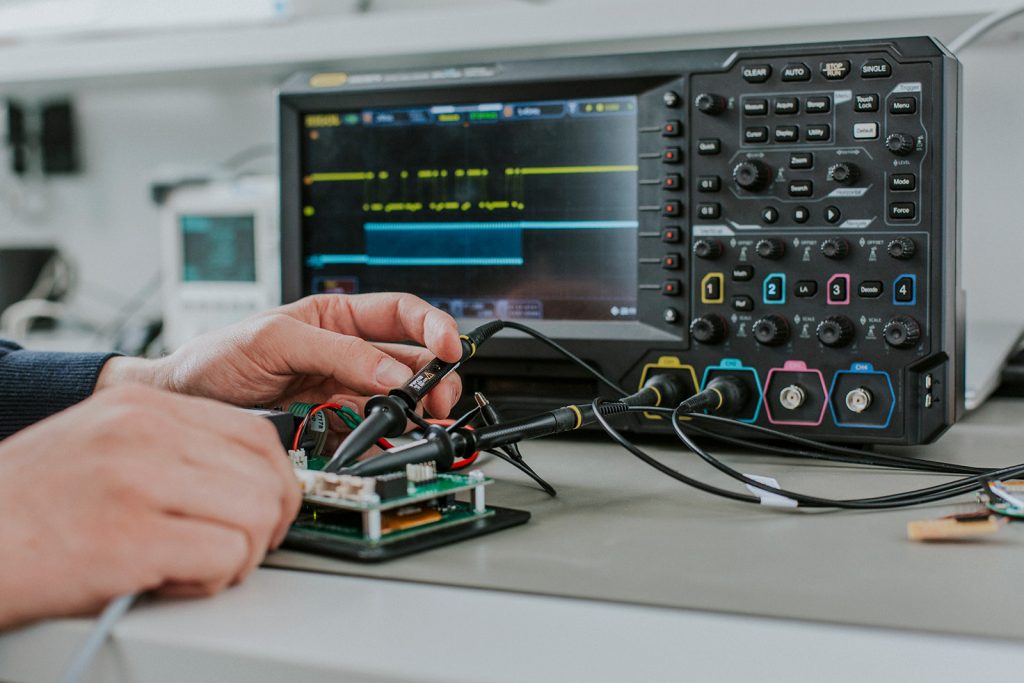

ELECTRONICS-MECHANICAL INTEGRATION

Our cross-disciplinary team ensures that mechanical and electronic components fit together perfectly. We start by mapping out all the elements – circuit boards, connectors, displays, sensors – that need to co-exist within the product, and we design the enclosure around these requirements. This holistic approach eliminates the common “will it fit?” headaches. We also account for things like thermal management, cabling, antenna placement, and environmental sealing during the design. The result is a cohesive product design where hardware and housing work in harmony, delivering reliable performance under real-world conditions and simplifying assembly and testing.

Why it Matters:

- Mechanical design influences usability, durability, and cost

- Early engineering decisions affect timelines and scaling

- Great hardware needs great enclosures to succeed

TECHNICAL KNOW-HOW

Our Expertise

We work with and innovation teams. We provide organization, experienced engineering help, and smart technical advice from your first idea all the way to launch.

ENCLOSURE AND STRUCTURAL DESIGN

From sleek housings to complex mechanical assemblies — we design the parts that protect, support, and define your product.

USER-FOCUSED MECHANICAL ENGINEERING

We understand that the enclosure is often the first thing users touch — it needs to feel right, work intuitively, and last.

INDUSTRIAL DESIGN MEETS ENGINEERING

Our team blends creative industrial design with precise mechanical engineering to deliver robust, reliable results.

DESIGN FOR MANUFACTURING (DFM)

We apply DFM principles from the start to:

- Reduce development risks

- Avoid costly redesigns

- Enable a smooth path to mass production

SUPPORT FROM PROTOTYPE TO PRODUCTION

Whether you’re building a proof-of-concept or preparing for large-volume manufacturing, we help you get there — faster and smarter.

Frequently Asked Questions

Can you design enclosures that meet industry standards?

Yes. We design enclosures that comply with IP ratings, thermal requirements, and other regulatory standards, ensuring readiness for real-world use.

Do you support rapid prototyping?

Absolutely. We use 3D printing and CNC machining to quickly validate designs and refine products before production.

How do you ensure designs are production-ready?

We apply Design for Manufacturing (DFM) principles from day one, ensuring efficient, cost-effective, and consistent mass production.

Do you integrate mechanical design with electronics?

Yes. We collaborate closely with electronics engineers to ensure seamless integration of mechanical components, PCBs, and other electronics.

GET IN TOUCH

Want to see how our expertise fits your needs? Reach out.

Thank you, your message has been sent!

We got your message, our team will get in touch with you really soon, until then, explore our website.