SERVICES

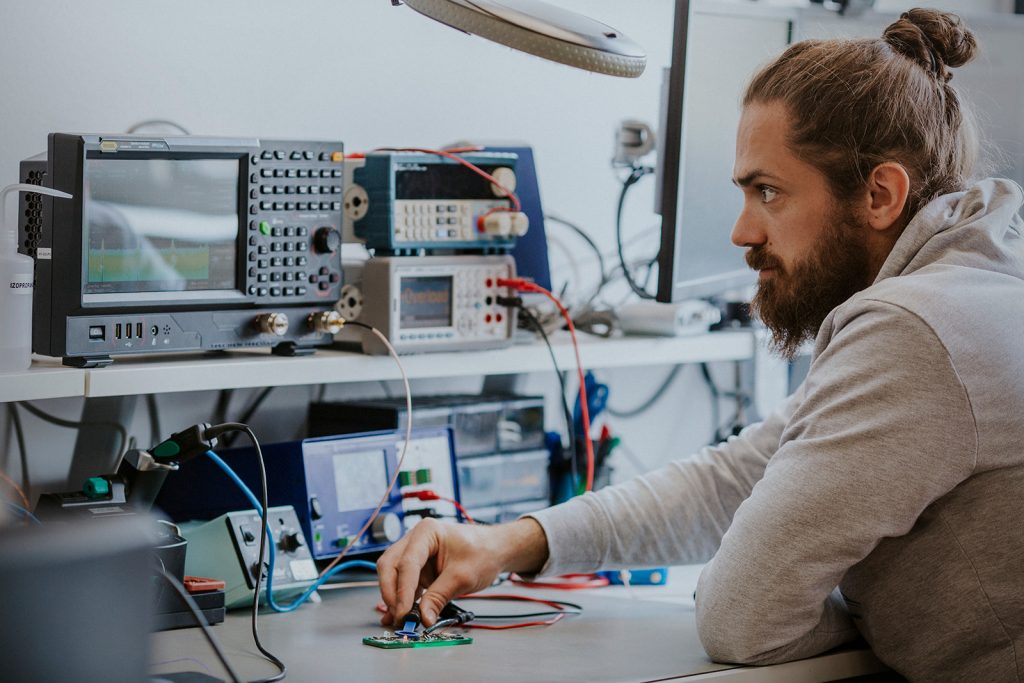

Embedded Hardware Development

At Byte Lab, we specialize in embedded hardware development, from PCB design to prototyping and production support.

Our engineers design custom electronic hardware optimized for performance, reliability, and manufacturability. Whether you’re building a connected device, IoT product, or a complex embedded system, we help bring your hardware from concept to production with confidence.

EXPERTISE IN ACTION

Services We Offer

Each of these services is delivered through a structured and well-defined project execution framework. From initial planning to final delivery, we follow clear procedures and assign dedicated roles to manage every stage of development effectively.

HARDWARE DEVELOPMENT

We offer comprehensive hardware development services, including schematic design, PCB layout, hardware prototyping, and validation. Our approach ensures your hardware is optimized for functionality, performance, cost-efficiency, manufacturability, and compliance with industry standards.

HARDWARE DESIGN REVIEW

Our engineers perform detailed design reviews, covering schematics, PCB layouts, component selection, and system integration. We identify risks early, suggest improvements, and ensure your hardware design is reliable, robust, and ready for manufacturing and certification.

CUSTOM ANNTENNA DESIGN AND RESEARCH

Our team specializes in custom antenna design, ensuring your products achieve reliable and high-performance connectivity. We design antennas tailored to your specific requirements, covering a wide range of wireless protocols (Wi-Fi, Bluetooth, LoRaWAN, LTE-M, and more). Our services include simulation, prototyping, performance testing, and validation within your device’s mechanical constraints. We also conduct advanced research into antenna technologies, enabling integration of custom solutions that meet the most demanding performance criteria, including low power, size constraints, and challenging electromagnetic environments.

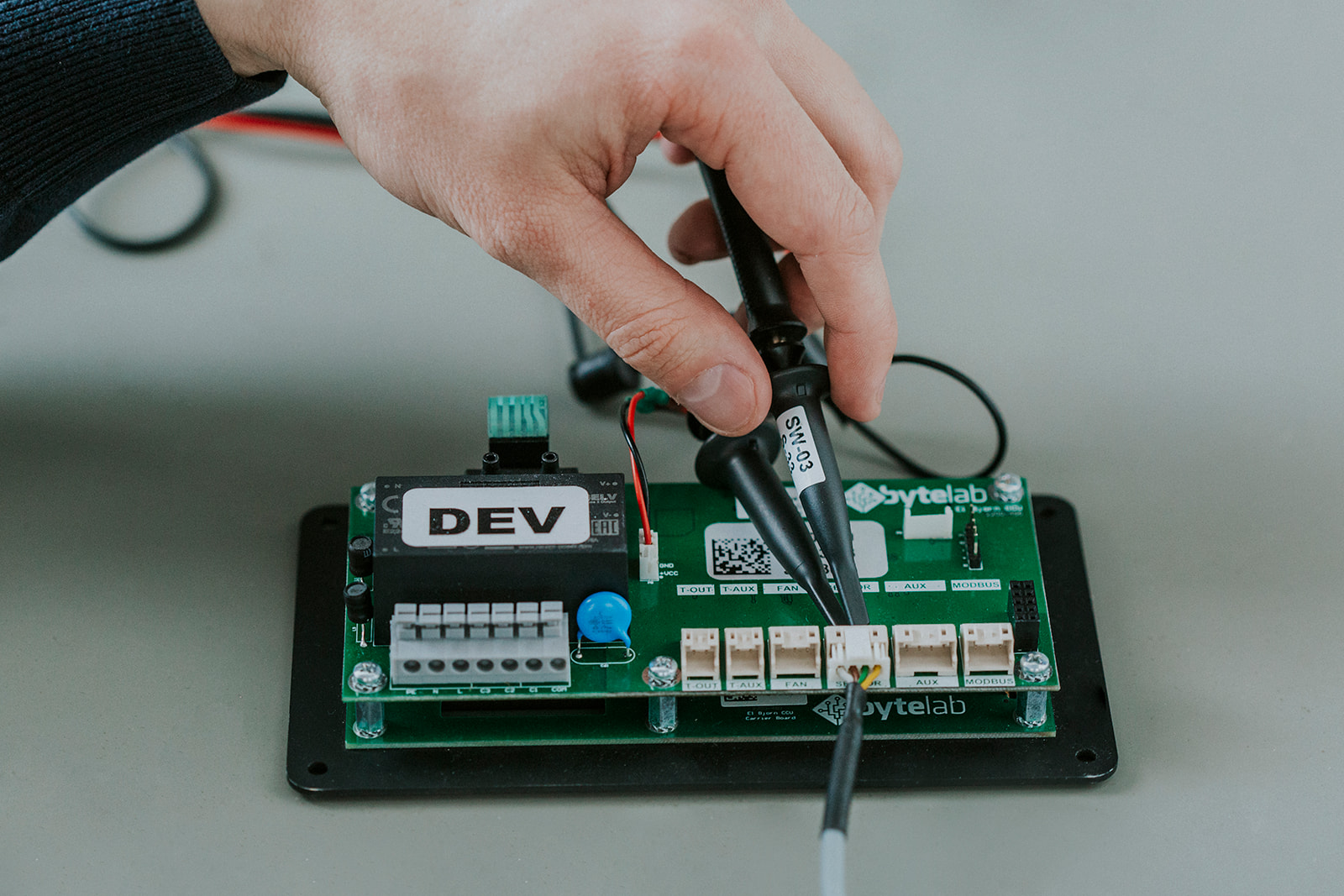

HARDWARE DESIGN VERIFICATION TESTING

Our validation services ensure your electronic designs meet functional, safety, and regulatory requirements before mass production. We verify power supply stability and efficiency, use thermal imaging to detect hotspots, and ensure crystal oscillator accuracy. We also test external accessories for compatibility, conduct real-world integration testing, and provide EMC pre-compliance testing (conducted and radiated emissions, ESD). Our processes help deliver robust, reliable hardware ready for certification and production.

CUSTOM END-OF-LINE (EOL) TEST JIG DESIGN

We design and develop custom test jigs and end-of-line testing protocols tailored to your product. This includes mechanical design, hardware customization using Byte Lab’s proven templates, and test protocol development — ensuring every unit meets quality standards before shipping.

CERTIFICATION SUPPORT

We guide you through regulatory certification processes such as CE, FCC, UL, ISO, and other standards. Our support includes design compliance reviews, preparing documentation, pre-certification testing, and coordinating with certification bodies to streamline the approval process.

MANUFACTORING SUPPORT

We offer BOM optimization and preparation for large-scale manufacturing, ensuring cost-efficient production and seamless handover to your manufacturing partners.

DESIGN REVIEW

We know the value of a second pair of eyes. Our detailed design reviews cover schematics, PCB layouts, component selection, and system integration. We help you identify risks early, suggest improvements, and ensure your hardware design is rock-solid and ready for manufacturing and certification.

FEASIBILITY ANALYSIS

We help you de-risk your project from day one. Our team validates early concepts and assesses technical feasibility, giving you confidence before you commit to full-scale development.

PRODUCT TEARDOWN & ANALYSIS

We analyze competitive products and reverse-engineer solutions to understand what works (and what doesn’t). This gives you a strategic edge when defining your own product’s features and performance.

Industries We Serve

Industrial Automation

Real-time control systems, sensor integration, and connectivity solutions for industrial IoT (IIoT) applications.

Consumer Electronics

Smart home devices, wearables, and entertainment systems with seamless connectivity and intuitive user interfaces.

Healthcare & Medical Devices

Reliable embedded systems for medical equipment, sensors, and monitoring devices ensuring patient safety and compliance.

Telecommunications

Firmware and embedded software for gateways, routers, and communication devices with support for LTE-M, NB-IoT, and other protocols.

Smart Energy & Utilities

Embedded solutions for energy meters, grid monitoring systems, and IoT-based smart infrastructure.

Aerospace & Defense

High-reliability embedded systems for mission-critical applications requiring robust connectivity and real-time performance.

TECHNICAL KOW-HOW

Our Expertise

Hardware is where it all begins. At Byte Lab, we combine hands-on engineering with real-world manufacturing know-how to design embedded hardware that actually works, and keeps working. From custom PCBs to fully integrated systems, we build with performance, reliability, and scale in mind.

CUSTOM ELECTRONICS DEVELOPMENT

Creating custom electronics can be challenging. But at Byte Lab, we know how to design systems that simply work, selecting the right components, defining how everything communicates, and balancing performance and cost to deliver products that are both reliable and scalable.

ANTENNA DESIGN

We make your product connect — perfectly. Connectivity can make or break a device, and our team has deep experience in custom antenna design and research. We ensure your device stays connected in any environment, no matter the mechanical or electromagnetic challenges.

PCB DESIGN

Using industry-leading tools like Altium Designer and KiCad, we create boards that are manufacturable, optimized for low power, and compliant with EMC standards — ensuring they perform not just in the lab but in the real world.

POWER SUPPLY DESIGN

Power is the heartbeat of every device. We design efficient, reliable, and stable power solutions that keep your electronics running under all conditions.

BOM OPTIMIZATION

We optimize hardware costs without compromising quality — from BOM optimization to component selection — ensuring your product meets its price point without sacrificing performance.

LOW POWER DESIGN

Our engineers specialize in low-power hardware design, creating solutions that extend battery life and deliver high efficiency for portable and battery-operated products.

DESIGN VALIDATION

Validation of design is key to building a quality product. We tailor testing and validation to each product’s unique requirements, ensuring every design is robust, reliable, and ready for production. Our processes adapt to your product’s complexity — from EVT, DVT, and PVT stages to thermal analysis, power validation, and real-world integration testing — catching issues before they reach the market.

INDUSTRIALZATION FOR MASS PRODUCTION

It’s not enough for a product to work on the bench. We optimize every design for manufacturability, so it can be built at scale — consistently, reliably, and cost-effectively.

CERTIFICATION

Our team knows how to get designs ready not just for the lab but for the world, ensuring they meet CE, FCC, UL, and other certifications — smoothly and on time.

Frequently Asked Questions

Do you support ultra-low power design for battery-operated devices?

Absolutely! Our expertise includes optimizing hardware for ultra-low power consumption, extending battery life, and ensuring energy efficiency.

Can you help with custom antenna design and integration?

Yes! We specialize in custom antenna design and research, ensuring your device meets connectivity requirements even in challenging mechanical and electromagnetic environments.

What kind of testing do you provide to ensure compliance and performance?

We offer a comprehensive suite of testing services, including design verification (EVT/DVT/PVT), EMC pre-compliance, and end-of-line test jig design. Our testing covers thermal, electrical, and mechanical aspects, ensuring your product is production-ready and certified.

Can you assist with certification processes like CE, FCC, UL, and ISO?

Yes, we provide complete certification support, including compliance design reviews, documentation preparation, pre-certification testing, and coordination with certification bodies to help you navigate regulatory processes efficiently.

Do you handle the entire hardware development cycle?

Yes! We can support you from concept design through to production, including architecture, PCB layout, testing, verification, certification, and manufacturing support.

GET IN TOUCH

Want to see how our expertise fits your needs? Reach out.

Thank you, your message has been sent!

We got your message, our team will get in touch with you really soon, until then, explore our website.