SERVICES

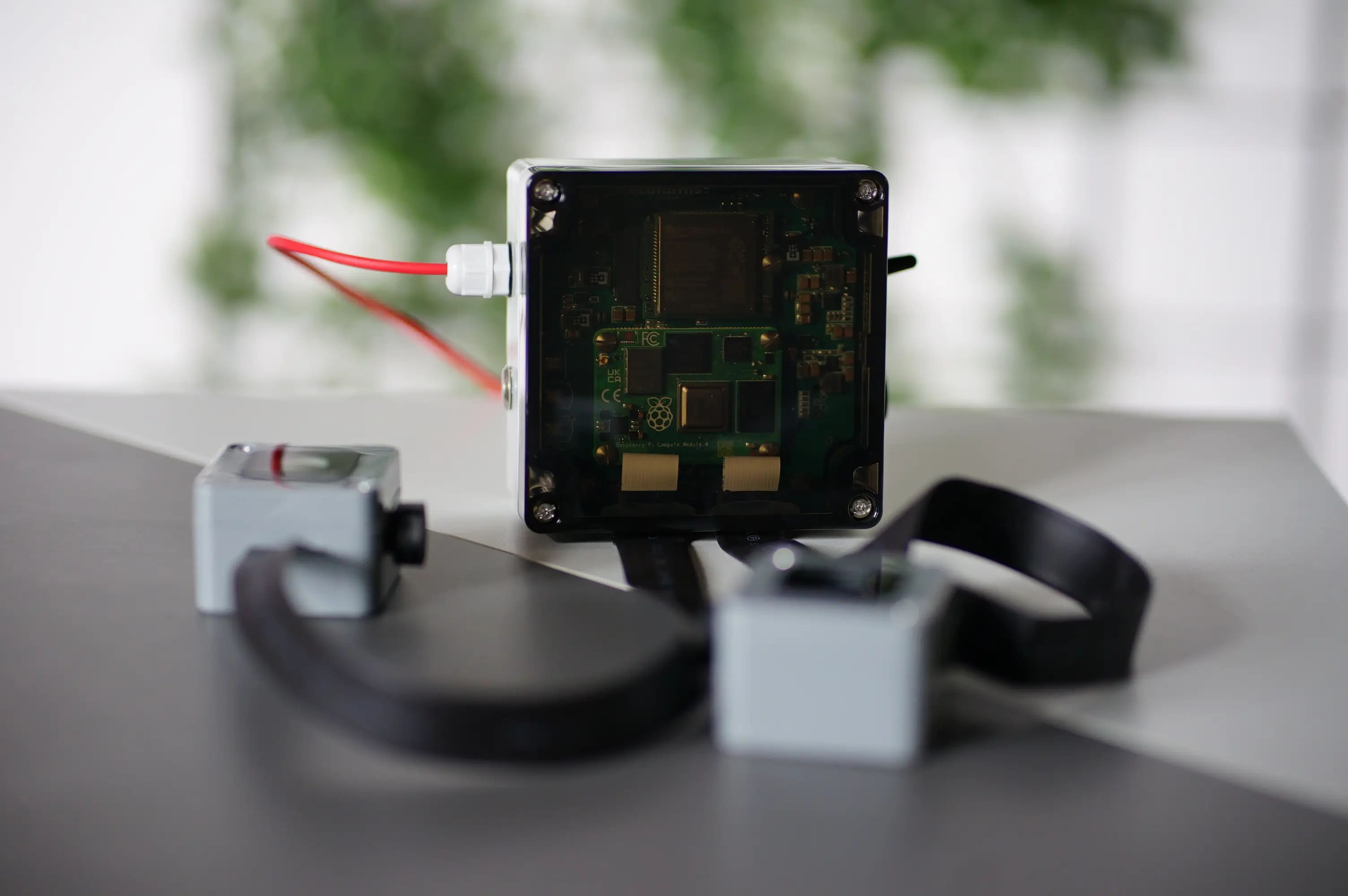

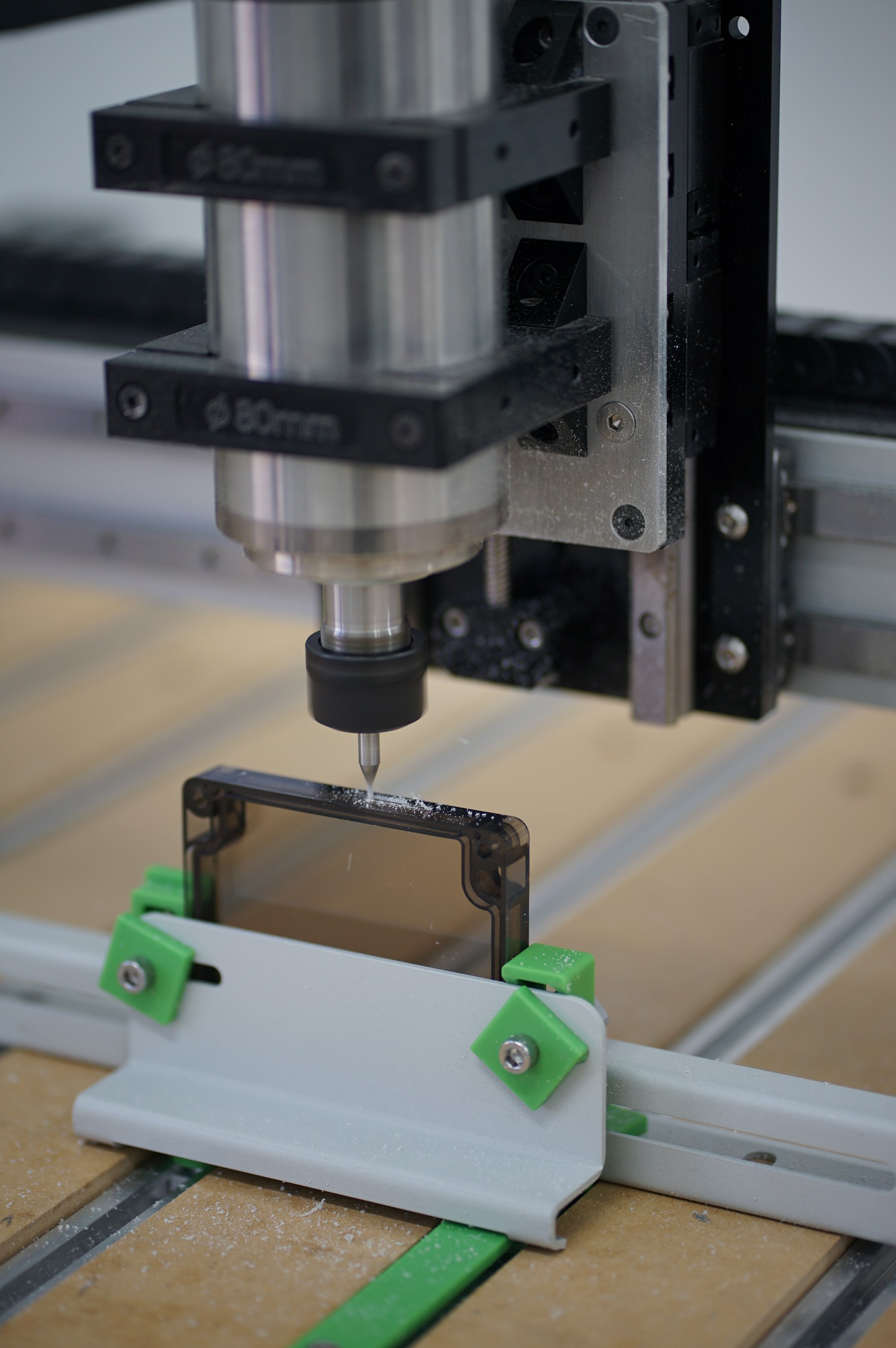

Box build assembly service

Box build assembly, also known as system integration, is a complete manufacturing solution that goes beyond PCB assembly.

What Our Box Build Assembly Services Include

Assembly of:

- Enclosures

- Wiring and cable harnesses

- Sub-assemblies

- Full product integration

End-to-end support

- Component sourcing

- Mechanical assembly

- Functional testing

Flexible solutions

- From simple PCB-in-a-box to fully assembled, user-ready devices

Benefits

- Faster time-to-market

- Consistent quality and precision

- Cost-effective manufacturing process

Need a hand with full product assembly?

We can take care of everything — from wiring to final testing.

Frequently Asked Questions

What is box build assembly?

Box build assembly, or system integration, is a comprehensive manufacturing service that includes assembling a complete electronic product. This process involves PCB integration, wiring, cable harnesses, enclosures, mechanical assembly, and functional testing.

What components are included in a box build assembly?

A typical box build includes the PCB assembly, enclosures, wiring and cable harnesses, sub-assemblies, labels, and any additional mechanical or electronic components required to create a fully functional product.

Do you handle component sourcing for box build projects?

Yes, we provide end-to-end services, including sourcing components, enclosures, and other materials, ensuring the highest quality and compliance with your specifications.

Can you customize the box build assembly process for my product?

Absolutely. Our team works closely with you to create a tailored solution that meets your product’s design, functionality, and performance requirements.

What industries do you serve with box build assembly?

We cater to a wide range of industries, including medical, automotive, consumer electronics, industrial equipment, telecommunications, and more.

Do you offer testing for box build assemblies?

Yes, we provide comprehensive testing, including functional tests, system-level tests, and quality inspections, to ensure the final product meets all performance and safety standards.

Can you manage small-volume and high-volume box build projects?

Yes, we have the flexibility and scalability to handle both small-batch custom projects and large-scale production runs.

How do you ensure the quality of box build assemblies?

Our quality control process includes thorough inspections, adherence to IPC and ISO standards, and rigorous functional testing to ensure each product meets your exact specifications.

What information do you need to start a box build project?

We require your bill of materials (BOM), product design files, assembly drawings, test requirements, and any specific instructions related to enclosures, labeling, or packaging.

Can you handle packaging and labeling for the finished product?

Yes, we provide packaging and labeling services, including custom packaging and serialized labels, ensuring your product is ready for shipment or distribution.

What are the lead times for box build assembly projects?

Lead times depend on the complexity of the assembly and volume of production. After reviewing your project requirements, we’ll provide a detailed timeline.

Do you offer support after delivery?

Yes, we offer post-delivery support, including warranty management, troubleshooting, and assistance with any issues related to the assembly.

Is box build assembly cost-effective?

By consolidating multiple manufacturing processes under one roof, we help reduce costs, improve efficiency, and streamline your supply chain for significant cost savings.

FILL OUT THE FORM

Request for quotation

Thank you, your message has been sent!

We got your message, our team will get in touch with you really soon, until then, explore our website.